Rubber vulcanizing Tester traders|rubber vulcanization chamber : wholesalers Rubber Vulcanizer is mainly used for rubber vulcanization, thermosetting plastics and insulation products of pression. This test machine has device of pressure, time, temperature automatic . WEB4 de nov. de 2022 · Jogo da Corrupção, nova temporada da série original Amazon Prime Video El Presidente estreia nesta sexta-feira (4/11). Inspirada nos escândalos que rodeiam a vida do ex-presidente da Fifa, .

{plog:ftitle_list}

WEBPKGJ: All Games Cover Art. https://www.mediafire.com/file/1msrd1aln4j6kds/cover.zip/file. Unzip and add folder to ux0:pkgj/. 81. Sort by: Add a Comment. YiYumagiccloud.

For measuring the unvulcanized rubber characteristics to identify the optimum cure time. Characters: 1. Imported intelligent digital temperature controller, easy adjust settings, a wide range of temperature. control, high control accuracy, .

We provide a detailed explanation of the Rubber Vulcanization Process, including the role of the vulcanizing agent, temperature control, and reaction mechanisms. Manufacturer and distributor of rubber vulcanizers for belt or splicing applications. Available in 24.6 to 84 in. length, 6 in. width, 9.6 to 12.8 in. overall height and 28 psi pressure .Manufacturer and distributor of rubber vulcanizers for belt or splicing applications. Available in 24.6 to 84 in. length, 6 in. width, 9.6 to 12.8 in. overall height and 28 psi pressure or 200 .

Rubber Vulcanizer is mainly used for rubber vulcanization, thermosetting plastics and insulation products of pression. This test machine has device of pressure, time, temperature automatic .The first process, called Pressure Vulcanization involves heating the rubber with sulfur under pressure, with a temperature of 150C. The second process, called Free Vulcanization, simply .1.1 These test methods cover procedures used to evaluate the tensile (tension) properties of vulcanized thermoset rubbers and thermoplastic elastomers. These methods are not appli . Discover how vulcanization enhances the durability, strength, and performance of rubber, making it an essential component in countless industries. Through an engaging visual journey, we will .

7.1.4 Other test specimen sizes may be used as dictated by end use. 7.2 The Þrst three test specimens described above were evaluated in interlaboratory testing. The washer type test specimen ( 7.1.3 ) is preferred. 7.3 Preparation of Test SpecimensÑ Test specimens may be prepared by taking a sample of the compound or material of interest.In this chapter we will direct out attention to the test procedures and instruments used to measure two of the most critical properties of rubber and rubber compounds, processibility and vulcanization.These characteristics are vitally important because they define the operating window available for converting uncured rubber compound into a usable product.5.1 This test method is used to determine the vulcanization characteristics of (vulcanizable) rubber compounds. 5.2 This test method may be used for quality control in rubber manufacturing processes, for research and development testing of raw-rubber compounded in an evaluation formula-tion, and for evaluating various raw materials used in .

Learn about Rubber compounding: https://youtu.be/yK6-QNB1roo?si=jzlrsKFDhkssuCTpThis video explains the basics of the rubber vulcanization process, including.Mooney Viscosity. The Mooney Viscosity test is a well-established method for characterizing uncured rubber materials. Following well- defined standard procedures, the sample is preheated for a defined period, then sheared at a constant rate.The Mooney Viscosity is recorded from the end of this deformation stage. in the present example, the outstanding precision of the MVone .Vulcanizaton of rubber products: Frame Plate Vulcanizing Press is usually used to vulcanise unvulcanised rubber products, so as to achieve the purpose of enhancing their elasticity and abrasion resistance. Such as road speed bumps, etc. Tyre manufacturing: the equipment can be used to vulcanise various parts of tyres, such as tread, sidewall and inner liner, so it is adapted .Worker placing a tire in a mold before vulcanization. Vulcanization (British English: vulcanisation) is a range of processes for hardening rubbers. [1] The term originally referred exclusively to the treatment of natural rubber with sulfur, which remains the most common practice.It has also grown to include the hardening of other (synthetic) rubbers via various means.

PROCESSING AND VULCANIZATION TESTS 109 DIE RUBBER LOWER DIE ROTOR Fig. 4.2. Mooney chamber and rotor. flow) during the test are indicated by a low plasticity number. . Standard gives standard test conditions for raw rubber viscosity measurements. Results of a typical test are normally reported as follows: 50-ML 1 + 4 (100°C) where 50-M is .

Vulcanization is a process generally applied to rubbery or elastomeric materials. These materials forcibly retract to their approximately original shape after a rather large mechanically imposed deformation. Vulcanization can be defined as a process that increases the retractile force and reduces the amount of permanent deformation remaining after removal of the deforming force.D2084 Test Method for Rubber Property—Vulcanization Using Oscillating Disk Cure Meter D5289 Test Method for Rubber Property—Vulcanization . 4.1.1 The materials required for standard rubber test formu-las shall be Industry Reference Materials (IRM) as specified in Specification D5900. The current list of Industry Reference An international standard, ISO 2921:2019 – Rubber, Vulcanized – Determination Of Low-Temperature Characteristics – Temperature-Retraction Procedure (TR Test), helps test vulcanized rubber. Vulcan is the Roman god of fire, metalworking, and the forge. He’s even where we get the word “volcano”— the Italian volcano derives from the Latin Vulcanus.

rubber vulcanizing machine

By the tensile testing of a rubber vulcanized three promaters it; the tensile strength, elongation at break and modulus at a particular elongation of the sample are obtained at a time. Tensile strength is defined as the force per unit area of original cross section of the sample, required to stretch the original cross section of the sample .The story and science behind one of the most important developments in polymer science. How is vulcanized rubber made? Why is it important? In what applicati.

vulcanization of rubber test mixes specified in the various International Standards for the evaluation of such test mixes. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies.

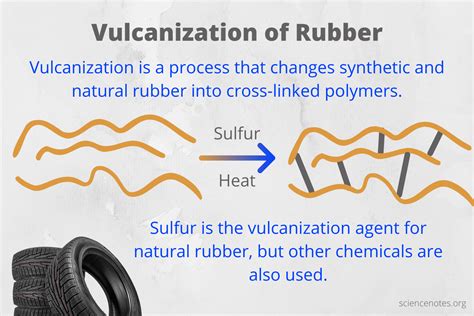

Mooney viscosity, scorch and relaxation test of rubber compounds (ISO289-1 to 4) Mooney viscometer (MV2000E) . Vulcanization characteristics (MDR2000E) ISO6502. Determination of processing characteristics of uncured rubber .K-12 Lesson Plan: Because polymers are such large molecules, the intermolecular forces between polymer chains are stronger than most other organic substances. Rubber, despite our general suppositions on how phases of matter should behave, is a liquid at room temperature (it will flow over time). Due to the strong intermolecular forces present (van der Waal . Vulcanization of rubber uses heat and sulfur (or another chemical) to form a hardened cross-linked polymer. Vulcanization or vulcanisation (British) is a process of hardening rubber using chemicals and .

SKZ131 ASTM D5289 ISO6502 Rotor-less Curemeter Rubber Vulcanizing Tester-Cure Meter. For measuring the unvulcanized rubber traits to discover the best therapy time. Standard: ASTM D5289, ISO6502, T30,T60,T90. Technical parameters:Ask the Chatbot a Question Ask the Chatbot a Question vulcanization, chemical process by which the physical properties of natural or synthetic rubber are improved; finished rubber has higher tensile strength and resistance to swelling and abrasion, and is elastic over a greater range of temperatures. In its simplest form, vulcanization is brought about by heating rubber with . In naming this process, he chose to call his discovery vulcanization, after the Roman god of fire: Vulcan. Today, rubber comes both naturally from the rubber tree and from artificial sources. Vulcanization remains crucial for making rubber stronger, and vulcanized rubber is often the type of the material in contact with the average person.

ASTM D624 is a common test method used to determine the tear strength of vulcanized rubber and thermoplastic elastomers. Due to the specimen shapes often used, this test is sometimes called a trouser, angle, or crescent test. In this investigation, MgO was employed as a secondary cure activator to decrease the rubber curing temperature. To study the curing kinetics at various temperatures, the moving die rheometer (MDR) measurement technique was utilized, and Coran kinetic models of accelerated sulfur vulcanization were adopted. Results from the curing studies revealed that .on the shape of the test piece. The rubber-to-metal bond is sometimes subjected to a combination of stresses (see Figure 1). . Based on ASTM D 429 and DIN 53531, a rubber coating is vulcanized onto a 240 x 25 x 6 mm metal strip , and then peeled off at an angle of 90° at a rate of 50 mm/min. This test, corresponding closely to . A Beginner's Guide to Rubber: Rubber Vulcanization. There are many ways to form rubber parts, part 3 of this guide will discuss the remaining more popular processes used in the industry today. As mentioned earlier, the process for turning rubber compounds into usable finished products is vulcanization. There are various types of vulcanization .

The vulcanization requires quite a lot of resin: 5–12 phr, together with some parts SnCl 2.2H 2 O as a Lewis acid. The vulcanization proceeds rather slow, but good compression sets are obtained and very good thermal properties. Resin vulcanization of IIR is especially applied in the manufacturing of bladders for tire vulcanization.

rubber vulcanization process

Gas Permeability Test System mfg

IS 3400 (Part 2) :1995 Methods of test Technically for vulcanized rubbers: Part 2 Hardness equivalent with (second revision) minor deviation IS 13867:1993 Rubber standard do temperatures, humidities and times for the conditioning and time interval between vulcanization and testing of test pieces

Making Rubber Stronger Through Vulcanization. Rubber is a polymer of isoprene that is formed with double bonds between each of the individual monomers (or units). In simple terms, one of these bonds is flexible and can allow the polymer to take up many shapes and sizes, which is what basically gives rubber its property of elasticity.

Gas Permeability Test System trade

rubber vulcanization chamber

WEBMarília Selo de Influência Fatal Model. Este anúncio pertence a uma pessoa Embaixadora ou Influenciadora produtora de conteúdo do Fatal Model. . Mídias de comparação é o sistema que o Fatal Model usa visando gerar mais credibilidade aos perfis. Todas as mídias de comparação são analisadas por nossa equipe. Lembre-se: .

Rubber vulcanizing Tester traders|rubber vulcanization chamber